Here's something that's puzzled me: Lean Manufacturing and Ergonomics are trying to solve the same problems, but they're often treated like they live in completely different worlds.

Walk into most manufacturing facilities and you'll find lean practitioners mapping value streams, running Kaizen events and implementing 5S with military precision. Meanwhile, the Ergonomics team (if there is one) is off conducting their own assessments, often after someone's already hurt.

It doesn't make sense. Both disciplines are fundamentally about eliminating waste, improving efficiency and making work better. So why aren't we joining forces?

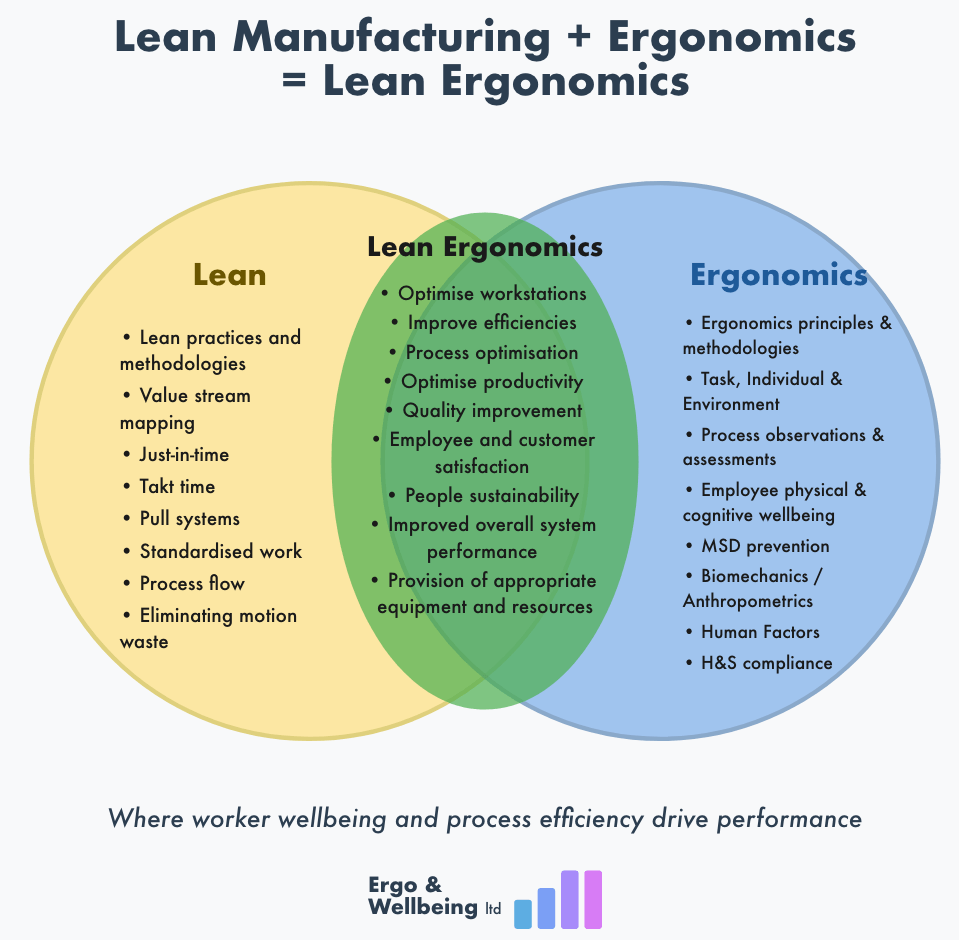

The diagram below illustrates just how much overlap exists between these two disciplines. From optimising workstations to improving system performance, lean and Ergonomics share far more common ground than most people realise.

The Missed Opportunity

Across the manufacturing sector, there's a common pattern: lean teams optimise production lines for cycle time and material flow, while Ergonomics assessments happen separately, often reactively rather than proactively. Both teams are working towards better outcomes, but they're rarely in the same room at the same time.

It's a missed opportunity. Ergonomic injuries are waste. They're Muri (overburdening workers), they create Mura (inconsistency when fatigued workers slow down) and they definitely create Muda (lost time injuries, reduced quality, compensation claims). If we're serious about lean, we can't ignore the human element.

What Lean Ergonomics Actually Looks Like

Imagine integrating Ergonomics thinking into the lean tools you already use:

Gemba Walks with Ergonomic Eyes

Instead of just observing process flow, watch for repeated awkward postures, excessive reaching or forceful exertions. That operator twisting their torso 50 times an hour? That's waste you can eliminate.

Kaizen Events That Include Ergonomics

Traditional Kaizen events focus on reducing cycle time, eliminating motion waste and improving flow. But what if you added one more question to your improvement brainstorm: "Does this change reduce physical strain?"

A workstation height adjustment might add 30 seconds to your implementation plan, but it could prevent months of accumulated fatigue that eventually slows your operator down or leads to injury. During the event, have someone simulate the proposed changes, actually stand at the workstation and go through the motions. Does the new layout require less bending, twisting or reaching? Are tools positioned where they're naturally comfortable to grab? These aren't separate Ergonomic projects, they're just smart questions to ask whilst you're already improving the process.

Error-Proofing Workstations to Prevent Strain

Error-proofing is brilliant lean thinking: design systems so mistakes are impossible or immediately obvious. Why not apply the same logic to physical strain?

Instead of training operators to "maintain good posture," design workstations where poor posture is physically difficult. Tilt tables that bring work up to the operator eliminate the need to bend. Spring-balanced tool arms mean workers don't have to support heavy tools. Adjustable chairs with proper lumbar support make slouching less comfortable than sitting correctly.

You're not relying on the worker to remember Ergonomic training when they're tired at the end of a shift, you've engineered the problem away. That's poka-yoke thinking applied to human factors.

5S + Ergonomics

5S is about organising workspaces for efficiency: Sort, Set in Order, Shine, Standardise, Sustain. When you're doing the "Set in Order" step, think beyond just visual management and accessibility—consider biomechanics too.

Consider optimal reach zones and heights when placing frequently used items. Place them between shoulder and knuckle height, within easy reach without extending the arm fully. Heavy items should be stored between knuckle and waist height, never above shoulder or below knee level. Tools that are used together should be grouped so the operator can flow naturally from one task to the next without twisting or overreaching.

This isn't extra work—you're already deciding where things go during 5S implementation. You're just making those decisions with an Ergonomic lens. The workspace becomes not just tidier and more organised, but biomechanically smarter too.

Kanban That Asks: Are Workers Fatigued? Is the Physical Demand Too High? Is Repetitive Strain Slowing Them Down?

Kanban systems provide visual signals about workflow and inventory. They help you spot bottlenecks quickly—if work is piling up at a particular station, something's wrong.

But here's what often gets missed: sometimes that bottleneck isn't about machine capacity or material supply. Sometimes the operator is falling behind because the physical demands of the task are causing fatigue. They start the shift hitting target cycle times, but by mid-afternoon they're slowing down.

Visual management of workflow should include physical load. If a workstation consistently has parts waiting, don't just assume it's a skill issue or that the operator needs to work faster. Investigate whether physical fatigue is the real bottleneck. Are they doing repetitive forceful exertions? Awkward postures? Excessive reaching?

Address the Ergonomic root cause and that bottleneck often disappears—no additional headcount required.

The Business Case Writes Itself

When manufacturing sites properly integrate Ergonomics with Lean, the expected gains include:

Productivity improvements when workers aren't fighting their workstations

Quality improvements because less fatigued workers perform better and make fewer errors

Reduced labour costs from fewer injuries and less absenteeism

Faster cycle times when unnecessary movements are eliminated

Better employee engagement because workers feel valued

Simple changes—adjusting workstation heights, repositioning tools within easy reach, reducing repetitive twisting—can yield meaningful cycle time reductions. These aren't revolutionary technologies, just basic Ergonomic principles applied during lean improvement events.

Why This Doesn't Happen More Often

Usually, it's organisational silos. Lean sits in operations. Health and safety (where Ergonomics often lives) is separate. They have different KPIs, different meetings and different consultants.

Sometimes it's a misconception that Ergonomics is just about reactive injury management rather than proactive design. Or that it's "soft" compared to the hard metrics of lean.

But here's the thing: if you're measuring Overall Equipment Effectiveness (OEE) but not considering human effectiveness, you're only seeing half the picture.

Where to Start

You don't need to overhaul everything. Start small:

Invite an Ergonomist to your next Kaizen event. See what insights emerge when you have someone looking at human factors alongside process flow.

Add Ergonomic risk to your value stream mapping. Where are the physical hotspots in your process?

Include "reduces physical strain" as a criterion in your improvement prioritisation matrix. Not every improvement needs to address Ergonomics, but it should at least be considered.

Train your lean champions in basic Ergonomic principles. They don't need to become Chartered Ergonomists, but they should recognise red flags.

Measure it. Track musculoskeletal disorder rates alongside your other lean metrics. What gets measured gets managed.

The Bottom Line

Lean manufacturing and Ergonomics are separate disciplines, but keeping them in separate silos ignores how much they have in common—far more than most people realise. Both aim to eliminate waste, improve efficiency and create better outcomes.

The real waste is treating them separately.

When you integrate Ergonomic thinking into lean practices from the start, you design better solutions faster, avoid costly retrofits and create workplaces where both productivity and people thrive.

Isn't that what lean is supposed to be about?

Ready to Integrate Ergonomics into Your Lean Programme?

If you're running Kaizen events, implementing lean improvements or looking to eliminate waste in your manufacturing processes, adding an Ergonomics lens could unlock gains you're currently missing.

Visit our Lean Ergonomics page to learn more about how we integrate these disciplines.

Whether you need support with a specific project or want to train your lean champions to recognise Ergonomics risks, I'd be happy to discuss how we can work together. Let's go Lean Ergonomics!

Get in touch!

About the Author

Julie Rainey MSc C.ErgHF MIHFES is a Chartered Ergonomist and Human Factors Specialist with manufacturing experience at Aston Martin and Airbus UK. She specialises in integrating Ergonomics into production systems and lean manufacturing environments across Northern Ireland and the UK.