Manufacturing excellence isn't just about machinery, processes and outputs, it's fundamentally about people. Yet Ergonomics remains one of the most underutilised tools in the manufacturing engineer's toolkit. When integrated properly, Ergonomics transforms not just worker wellbeing but your entire production system's performance.

Here's why manufacturing engineers should be thinking about Ergonomics at every stage of design and production.

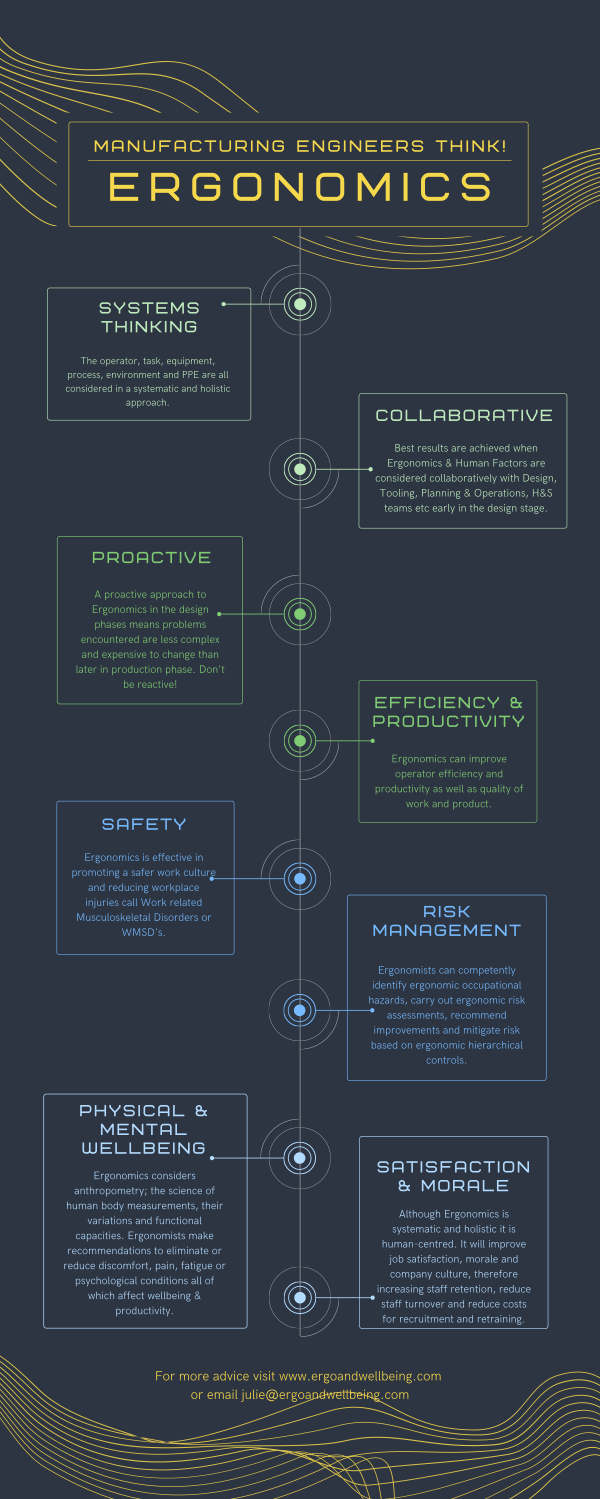

Systems Thinking: The Holistic Approach

Effective Ergonomics doesn't isolate problems, it examines the entire system. The operator, task, equipment, process, environment and PPE are all interconnected elements that must work together seamlessly.

This systematic and holistic approach means manufacturing engineers can identify bottlenecks and inefficiencies that single-focus improvements would miss. When you optimise one element in isolation, you risk creating problems elsewhere. Systems thinking prevents this by considering how changes ripple through your entire operation.

The result? More sustainable improvements that actually stick.

Collaborative Success: Ergonomics by Design

Best results are achieved when Ergonomics and Human Factors are considered collaboratively with Design, Tooling, Planning and Operations, and Health & Safety teams early in the design stage.

Too often, Ergonomics is an afterthought, brought in only when injuries occur or productivity flags. But involving Ergonomics expertise during the design phase means:

Fewer costly retrofits and redesigns

Equipment specified correctly from the start

Workstations designed for real human capabilities

Processes that support rather than fight operator performance

Cross-functional collaboration ensures everyone's priorities are balanced. Safety requirements don't compromise productivity, and efficiency gains don't sacrifice worker wellbeing.

Proactive Not Reactive: Design It Right First Time

A proactive approach to Ergonomics in the design phases means problems encountered are less complex and expensive to change than later in production phase. Don't be reactive!

Consider the cost difference:

Design stage: Considering workstation setup and dimensions through iterative CAD design, specifying appropriate tooling and equipment, evaluating process workflow

Production stage: Retrofitting installed workstations and equipment, managing injury claims, ongoing inefficiencies, investigating incidents

The financial case is clear. But there's also the human cost, workers experiencing discomfort, fatigue or injury while you wait to implement fixes. Proactive Ergonomics eliminates these entirely.

Efficiency and Productivity: Work Smarter Not Harder

Ergonomics can improve operator efficiency and productivity as well as quality of work and product.

When workstations suit human capabilities rather than fighting them:

Cycle times decrease naturally

Quality defects reduce

Operator fatigue diminishes

Consistent performance becomes easier to maintain

Training time shortens

This isn't about working harder, it's about removing barriers that prevent people from performing at their best. Small Ergonomic improvements often yield surprisingly large productivity gains because they eliminate the constant micro-adjustments and compensations workers make dozens of times per shift.

Safety: Reducing Workplace Injuries

Ergonomics is effective in promoting a safer work culture and reducing workplace injuries called Work-related Musculoskeletal Disorders or WMSDs.

WMSDs represent one of the largest categories of workplace injury, particularly in manufacturing. They develop gradually through repeated strain, awkward postures and excessive force, exactly the kind of hazards Ergonomics addresses.

Unlike acute injuries from obvious hazards, WMSDs often go unreported until they become serious. By then, you're dealing with:

Extended absences

Restricted duties

Compensation claims

Replacement and retraining costs

Lost experience and knowledge

Ergonomic interventions prevent these injuries before they start, creating a genuinely safer workplace rather than just reacting to incidents.

Risk Management: Systematic Hazard Control

Ergonomists can competently identify Ergonomic occupational hazards, carry out Ergonomic risk assessments, recommend improvements and mitigate risk based on Ergonomic hierarchical controls.

Professional Ergonomics applies the same rigorous risk management approach as other engineering disciplines:

Identify Ergonomic hazards systematically

Assess risks using validated methods

Control hazards following the hierarchy of controls

Monitor effectiveness and adjust

This evidence-based approach means recommendations are defensible, measurable and aligned with regulatory requirements. You're not guessing, you're applying proven methodology backed by decades of research.

Physical and Mental Wellbeing: The Complete Picture

Ergonomics considers anthropometry—the science of human body measurements, their variations and functional capacities. Ergonomists make recommendations to eliminate or reduce discomfort, pain, fatigue or psychological conditions, all of which affect wellbeing and productivity.

Manufacturing is demanding work, both physically and mentally. Ergonomics addresses both:

Physical wellbeing:

Reducing awkward postures and repetitive movements

Ensuring reach distances suit operator populations

Minimising force requirements

Providing adequate recovery time

Mental wellbeing:

Reducing cognitive overload through clear information design

Minimising time pressure and stress

Creating predictable, manageable workloads

Supporting focus and attention

Healthy workers are productive workers. When people aren't fighting discomfort or fatigue, they can focus on what actually matters, quality work.

Satisfaction and Morale: The Cultural Impact

Although Ergonomics is systematic and holistic, it is human-centred. It will improve job satisfaction, morale and company culture, therefore increasing staff retention, reducing staff turnover and reducing costs for recruitment and retraining.

The message you send matters. When manufacturing engineers prioritise Ergonomics, it demonstrates that the organisation values its people, not just as production units but as humans with needs and limits.

This cultural shift has measurable business impact:

Higher retention: Experienced workers stay longer

Better recruitment: Reputation as a good employer attracts talent

Increased engagement: Workers who feel valued contribute more

Improved communication: Collaborative approaches build trust

In tight labour markets, these cultural advantages provide genuine competitive edge.

Making It Happen: Integrating Ergonomics in Manufacturing

Understanding why Ergonomics matters is one thing. Actually integrating it into your manufacturing operations is another. Here's where to start:

Involve Ergonomics early: From concept design through to commissioning

Train your teams: Help engineers and supervisors recognise Ergonomic risks

Use validated tools: Apply proper assessment methods, not just intuition

Engage operators: They experience the work, listen to their insights

Measure outcomes: Track improvements in both worker wellbeing and performance

The Bottom Line

For manufacturing engineers, Ergonomics isn't a soft skill or ‘nice-to-have’, it's a fundamental engineering discipline that directly impacts your operation's success.

When you design work that suits human capabilities:

Productivity increases

Quality improves

Injuries decrease

Costs reduce

Culture strengthens

The question isn't whether you can afford to invest in Ergonomics. It's whether you can afford not to.

Learn More About Our Manufacturing Ergonomics Services

Need expert Ergonomics support for your manufacturing operation? Ergo & Wellbeing specialises in manufacturing Ergonomics, bringing Chartered Ergonomist expertise and real-world production experience from Aston Martin and Airbus UK. Whether you're designing new production lines, troubleshooting existing issues or need comprehensive Ergonomic assessments, we can help.

Contact us today to discuss how Ergonomics can transform your manufacturing performance.