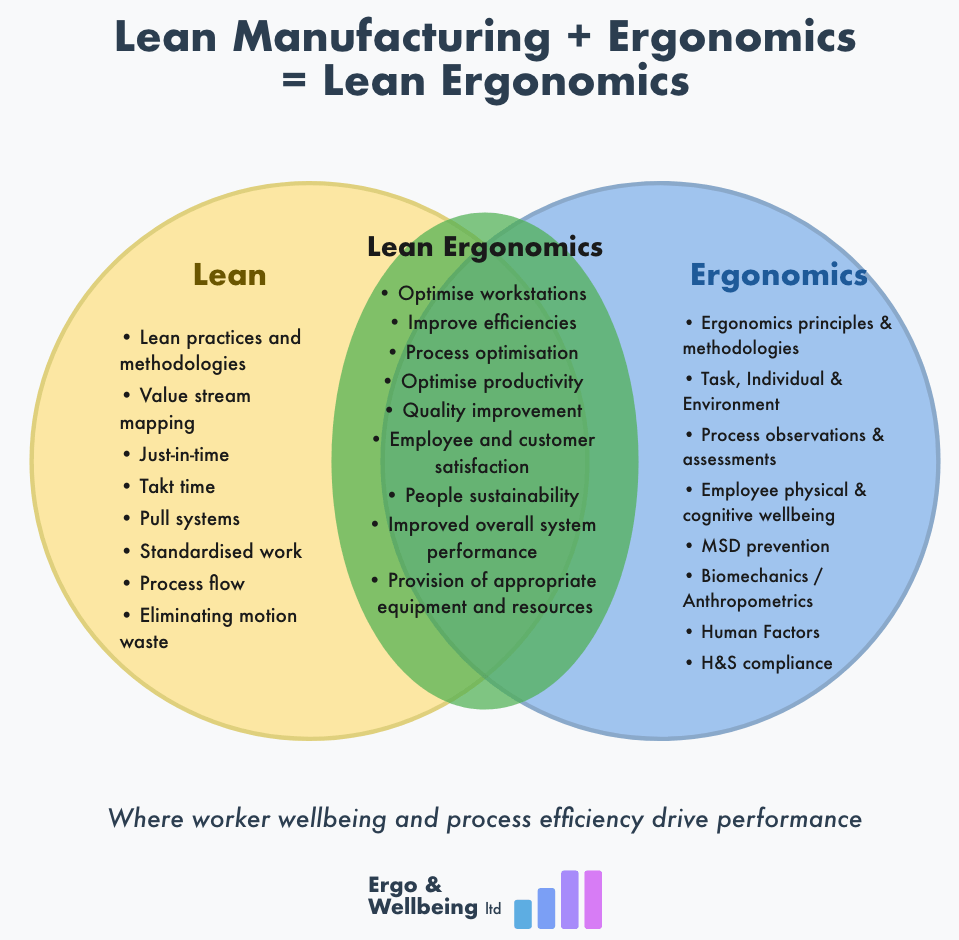

The Lean Ergonomics Advantage: Where worker wellbeing and process efficiency drive performance

Integrating Ergonomics with Lean Manufacturing

At Ergo & Wellbeing, we integrate Ergonomics with lean manufacturing principles. Most businesses treat these as separate disciplines, but we recognise they share the same goal: eliminating waste and optimising performance. Ergonomic injuries are a form of waste (Muda, Mura, Muri), and by addressing them through your existing lean tools—Gemba walks, Kaizen events, 5S, Poka-Yoke—you achieve better outcomes with less disruption.

The Benefits

1. Reduce Waste: Ergonomic injuries create Muda (lost time), Mura (inconsistency from fatigue), and Muri (overburdening workers). Addressing these through lean principles eliminates multiple forms of waste simultaneously.

2. Improve Productivity: When workers aren't fighting their workstations, productivity naturally increases. Optimised workspaces reduce fatigue and unnecessary movements, leading to faster cycle times.

3. Enhance Quality: Less fatigued workers make fewer errors. By integrating Ergonomics into your quality improvement processes, you create sustainable improvements in output quality.

4. Boost Employee Satisfaction: Workers feel valued when their wellbeing is considered in process design. This leads to better engagement, reduced absenteeism, and improved retention.

5. Achieve People Sustainability: Sustainable operations require sustainable people. Lean Ergonomics ensures your workforce can maintain performance levels without physical degradation over time.

6. Optimise System Performance: When you measure Overall Equipment Effectiveness (OEE) alongside human effectiveness, you see the complete picture and can optimise your entire system for peak performance.

Integrating Ergonomics with Your Existing Lean Tools

✓ Gemba Walks with Ergonomic Eyes - Observe not just process flow, but also awkward postures, excessive reaching, and forceful exertions that create waste.

✓ Kaizen Events That Include Biomechanics - Add one simple question to your improvement events: "Does this change reduce physical strain?"

✓ 5S Plus Ergonomics - Consider optimal reach zones and heights when placing frequently used items for biomechanically smarter workspaces.

✓ Poka-Yoke for Bodies - Design workstations where poor posture is physically difficult, not just discouraged through training.

✓ Kanban That Considers Load - Include physical load in your visual management. If work is piling up, investigate whether fatigue is the real bottleneck.

✓ Value Stream Mapping - Add Ergonomic risk to your value stream analysis to identify physical hotspots in your process.

Consider Lean Ergonomics – Where worker wellbeing and process efficiency drive performance

Ready to Integrate Ergonomics into Your Lean Programme?

Whether you need support with a specific project, want to train your lean champions to recognise Ergonomic risks, or are interested in our Lean Ergonomics awareness sessions, we're here to help. Get in touch.